The coolant tank (for a 360 Ferrari) was sent to me by a gentleman in Virgina who had asked if I could polish it. The same principles apply if you are polishing any piece of coated aluminum.

The first thing to do is strip the coating (powder coating or clear coating) You can use an automotive aircraft stripper, just spray it on (in a well ventilated area) and let it dwell for 15-30 minutes, until the finish bubbles up.

Use a fine brush (old tooth brush) to agitate any stubborn areas where the clear coat wants to stick. Then use a plastic scrapper to remove the clear coat and wash each wheel thoroughly.

Now you will have exposed the aluminum for polishing. If your aluminum has deep gouges or texture you will want to remove those by wet sanding each; starting with 220 grit and moving up to 1000 grit before polishing. Sanding them is extremely time consuming because you want to make sure you remove all of the previous sanding marks (from the rougher grit) before moving to the next finer grit.

You can accomplish this by cross-hatching. Sanding is one direction with say 220 grit, then sand in the opposite direction (left-to-right, then up-to-down) with say 400 grit until you no longer see the 220 grit marks, and repeat finer and finer.

When it comes time to polish the wheel to a super high luster (or remove the sanding marks) you are going to need an aluminum compound (similar to a compound for paint in principle), and then follow it up with an aluminum (fine cut) polish.

The Blackfire Aluminum Polishing Kit was (to my knowledge) the first boutique line of aluminum polishes that delivers professional results to the end-user. It is an idea that has been replicated (although perhaps not equaled).

You will need to have skill with a machine polisher how ever to use it.

Here is a link to the system and directions at out store: Coming soon to Autopia-CarCare.com

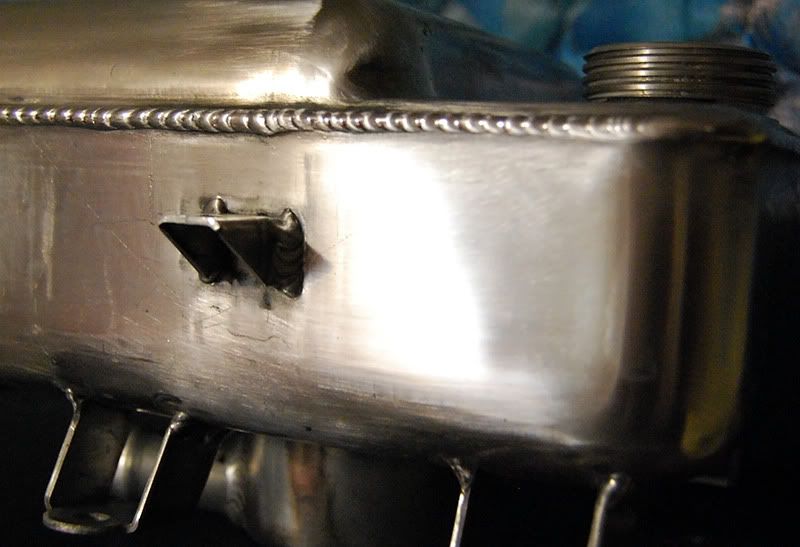

Here is a coolant tank from a Ferrari (that is actually a much cheaper casting of aluminum and much harder to polish and make look good).

The first step was using an aircraft stripper to remove the black powder coat (or in your case the factory clear). You can pick this up at just about any automotive supply store (Pepboys, Autozone, etc).

After removing all of the coating I could see that the casting was in terrible shape: factory casting scratches, texture, and deep cuts everywhere!

I tried polishing a test spot to see how the results would turn out.

The amount of gloss I was able to get from the Blackfire Polishing System was impressive and only took minutes.

However a cropped area of the photo shows that there are still a lot of these very deep (you stick the tip of a pencil into them) scratches that meant I had to sand the tank. If your wheels are not heavily scratched (or have texture) you can go right to polishing!

The right side of the tank has been sanded to 1000 grit, the rest to 400 grit. You can see the uniformity in the sanding marks (cross-hatching). I did sand a couple areas to 3000 grit, but the Blackfire Aluminum Compound is so strong that it made no difference in the outcome.

In this picture the edge of the tank (reflecting the horse) has been polished with just the compound, the rest of the tank is just sanded.

On this piece I found it easier to use a Porter Cable 7242XP (DA) Polisher and 4 inch pads. I used a Lake Country 4 inch High Gloss Yellow Pad with the Blackfire Aluminum Compound. I worked at Speed 5 with firm pressure until the aluminum was really bleeding black and the polish started to become opaque. I pays to clean the pad frequently by pressing it against a cotton towel and turning it on.

Then I followed with Blackfire Fine Cut Aluminum Polish (step two) with a Lake Country 4 inch H20 Tangerine pad, starting at step 5 then slowing to step 3 when the polish began to breakdown/dry up. Again firm pressure.

The final step was Blackfire Wet Diamond Aluminum Show Polish on a 4 inch Lake Country Hi Gloss White Pad, speed 4 with moderate pressure until almost clear.

After cleaning thoroughly I used Blackfire Wet Diamond All-Metal Sealant to lock in the shine with out the use of solvents that can dull the highly polished surface.

The results....

You can achieve a true mirror like finish on your wheels with our kit, no doubt, but it will take a little bit of time and patience ... but be warned... Polishing aluminum (and stainless) is addictive, my wife hasn`t forgiven me for what I have down to our refrigerator and appliances in our kitchen

Results 1 to 15 of 70

-

07-18-2011, 03:32 PM #1

Using Blackfire Metal Polishing System to create a mirror finish on aluminum

-

07-18-2011, 03:33 PM #2

Re: Using Blackfire Metal Polishing System to create a mirror finish on aluminum

So from this...

to this...

-

07-18-2011, 05:14 PM #3

Re: Using Blackfire Metal Polishing System to create a mirror finish on aluminum

Very nice! Have you ever tried to smooth out cast aluminum to polish up? I`ve got a set of cast aluminum valve covers I`ve been working on and off for a while

I want to try some Blackfire metal polishes after seeing this.

-

07-18-2011, 10:33 PM #4

Re: Using Blackfire Metal Polishing System to create a mirror finish on aluminum

Todd,

Nice job, nice write up. May I ask if you`ve ever used this product on Stainless or does BlackFire make a product that is up to the task of Stainless Steel? Over the years I`ve found that Aluminum is relatively easy to polish when compared to Stainless. I polish a fair share of Stainless on any given week and I`m always looking for something better.

Keeping a flat surface flat is always the trick when polishing broad or long surfaces. It`s easy to create waves that the eye will zone in on when polishing aluminum. I use a couple of pieces of flat marble to wrap my sand paper around to keep things flat. On some surfaces such as an aluminum manifold it`s all about removing large quantities of aluminum while keeping the surface smooth. The intent here is to get the surface pores closed. Carbide bits designed to cut aluminum in a die grinder can be a real time saver here. Once it`s knocked down it`s the same old procedure of diminishing the cut of the abrasiveness of paper or polish. Good luck!A society willing to trade liberty for temporary security deserves neither and will lose both

ΜΟΛΩΝ ΛΑΒΕ

-

07-18-2011, 10:54 PM #5

Re: Using Blackfire Metal Polishing System to create a mirror finish on aluminum

Man... those results are just unreal! How did you get into the tight areas around the inlet/outlet tubes and mounting brackets with the PCXP? Or did you switch to some other smaller tool to do those areas (by hand perhaps)?

Charlie

Automotive Appearance Specialist - Serving Greater Lansing, Michigan

http://www.cchautoappearance.com/

-

07-19-2011, 07:01 AM #6

That looks great Todd. Aluminum polishing is dirty work and makes a mess of pads and towels.

The results with this product are impressive.

Im wondering what else they are dressing up in the engine bay of

this Ferrari.

-

07-19-2011, 07:47 AM #7

Re: Using Blackfire Metal Polishing System to create a mirror finish on aluminum

I`m eyeing this kit for the exhaust system on my vehicles. Especially the Audi, all that metal work polished up can be a true work of art.

Treat it like it`s the only one in the world.

-

07-19-2011, 08:18 AM #8

Re: Using Blackfire Metal Polishing System to create a mirror finish on aluminum

I haven`t tried to polish cast aluminum valve covers in the same vain that I did to this piece. I did polish a set of early 350 LT-1 finned valve covers using these products by hand with very good results, although the compound requires a lot of work by hand to make sure the abrasives are fully broken down and the resulting surface scouring is kept to a minimum. I would refer to GearHead`s reply for perhaps a more insightful answer.

Thank you GearHead.

Yes I have used the `system` on Stainless, although it sounds like my experience is far less than yours. Here is a pic of a Ferrari 360 muffler that I practiced polishing with various methods. I believe these two pics are after the Blackfire Metal Polishing system, although this thing has served as a test bed for various products (I even used 3M and Menzerna polishes on it as well as Causwell buffing wheel).

IME with Stainless, I needed to use more RPM and more pressure to `grind it` when cutting. However I was able to get the best results using the BFMP system (I should note that I am NOT good with a Causwell buffing wheel so it is not a fair comparison).

Thanks Charlie. Honestly I did those areas by hand with little pieces of a foam cutting pad that I cut into appropriate sized pieces. I think I was watching `Prison Break` on Netflix, so I settled in for a couple episodes and got to work

Thanks John. On that particular Ferrari I believe they also polished or painted the airbox covers and that`s it. It also made a mess of my clothes

Are you going to be doing the exhaust on the car or is it coming off? To get the best effect (particularly with the aggressive compound) you really need a machine polisher.

-

07-19-2011, 08:24 AM #9

Re: Using Blackfire Metal Polishing System to create a mirror finish on aluminum

I need the Blackfire system so I can do the rest of my exhaust.

-

07-19-2011, 08:29 AM #10

-

07-19-2011, 08:48 AM #11

-

07-19-2011, 11:25 AM #12

Re: Using Blackfire Metal Polishing System to create a mirror finish on aluminum

Very Cool Todd...

-

07-19-2011, 12:18 PM #13

Re: Using Blackfire Metal Polishing System to create a mirror finish on aluminum

Originally Posted by Todd Helme

Originally Posted by Todd Helme

I`m going to do everything with the exhaust on the car. The system is in mint condition, still looks like the day I bought it, I just want to absolutely gleam

And on my new daily driver, I plan to use it routinely to maintain the bling.

I have plenty of polishers. I have wool and regular foam pads. I have 4" size ones too for the small spaces. I guess I`m good to go. This will a project for the coming fall.Treat it like it`s the only one in the world.

-

07-19-2011, 12:43 PM #14

I`m wondering is the Wet Diamond AM`S something that will hold up to exhaust heat? We put Tubi`s on a 430 and Gran Cabrio. They look great when they are clean. I was more concerned about the heat from the 430 positioning.

-

07-19-2011, 01:06 PM #15

Re: Using Blackfire Metal Polishing System to create a mirror finish on aluminum

It should hold up to the heat, ( BF Metal Polish and compound are aircraft grade products ) If you try it let us know on how well their hold up from the high temps.

AutopiaForums is the place to be.

Remember to Shop Autopia-CarCare.com for your Detailing Needs!

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

Using the BLACKFIRE Metal Polishing System

By Todd@RUPES in forum BlackFireWax.comReplies: 17Last Post: 03-14-2014, 08:42 AM -

Using Blackfire Metal Polishing System to create a mirror finish on aluminum

By Todd@RUPES in forum Auto Detailing 101Replies: 16Last Post: 07-19-2011, 05:32 PM -

How to turn aluminum rims into mirror finish?

By JLui83 in forum Car DetailingReplies: 10Last Post: 09-18-2009, 09:29 AM -

Mirror Finish on Billet Aluminum??

By cheetoh in forum Car DetailingReplies: 3Last Post: 09-08-2008, 06:29 AM -

what process for mirror finish aluminum?

By blucpe in forum Auto Detailing 101Replies: 8Last Post: 08-12-2007, 12:25 PM

Reply With Quote

Reply With Quote

Bookmarks